It seems obvious, doesn’t it? Laminate flooring? Well, to cut laminate you use the finest tooth blade you can get and I had almost 200 m2 of flooring to get down. So when I started cutting my Formica brand flooring and discovered my (not so sharp) 60-tooth blade was grinding through the 10mm boards, I invested immediately in a quality 80-tooth blade.

Hmmmm… a terrifyingly short time later, my $55 investment was literally burning its way through the boards. My first call, of course, was to Formica. I might as well have been asking how to bake a cake – they didn’t have the faintest idea what should be used to cut the boards. Que?

A quick call to world # 1 blade maker, Irwin, confirmed that, yes, I needed TCT and kerf. The smoking blade had both! The suggestion from their resident expert was that I try a 100-tooth blade and keep it lubricated.

Off I went to my local tool specialist and duly invested $75 – this time on the best blade Irwin offered and another $10 on a stick of Mother Nature’s finest beeswax. No more than twenty cuts later, Irwin’s best was starting to smoke too! And let me clarify one thing, these boards were only 116mm wide!

Over to Bosch and another $75 investment, this time in a 96-tooth triple chip blade. Surely, this would do the job. Yet again, we were burning our way through the boards within a very short time.

What to do? That was three blades and better than $200 and no more than 30m2 of flooring laid. My budget didn’t allow for $1,500 in blades so I called a sharpening service. Shock! Horror! The quote to sharpen the blades was only marginally less than buying them new!

I called my local tool shop. They called Carba-Tec. Surely they would have a solution. They didn’t!

We decided to persevere with the 96-tooth long as possible. Let me tell you, that wasn’t long. We put the 100-tooth Irwin back in and used that until there was more smoke than sawdust. Finally, it was down to the 80-tooth again. Imagination, or was it really lasting longer than the 100 and 96 teeth blades? Not a lot longer, but definitely longer.

The chippie I was working with suggested we try his 60-tooth blade – it was well-used but still had a reasonable edge on it. Neither of us expected it to last long and we weren’t disappointed BUT, it had cut as many boards as the new 100-tooth blade had before we discarded it!

Was this a ‘light bulb moment’? As counter-intuitive as it seemed, I went and bought a new 40-tooth TCT blade. You guessed it… although it was getting pretty tired at the end, a $25 blade saw us through the entire job.

Ah yes, but what about chipping, I hear you ask. In fact, chipping was almost non-existent up until the very end of the job when it started to become obvious. But even then, chips were less than 2 – 3mm and easily hidden under the skirting.

So there you have it… less is more. An inexpensive (quality) 40-tooth TCT blade is the correct blade for the job. But don’t bother asking the experts. They haven’t got a clue.

Don’t know what laminate flooring is?

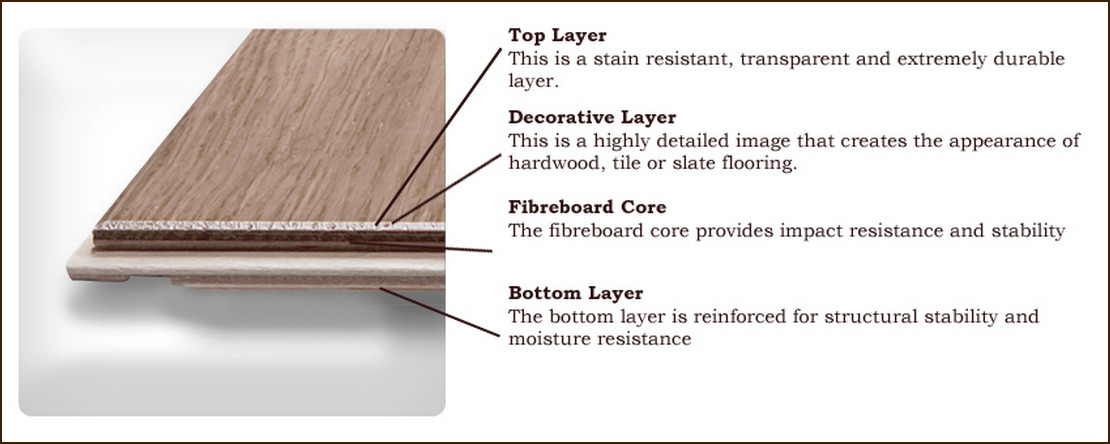

A laminate floor is a manufactured flooring made by fusing several layers of materials into a single board.

The central layer of the board is almost always high-density fibreboard, but sometimes only medium-density fibreboard (MDF) is used. Better quality boards are moisture resistant but are never recommended for wet area use.

The central core supports the weight and stress of foot traffic and will affect the durability and stability of your floor. Strength and stability are further ensured by the laminate’s bottom stabilizing layer. Like most things in life, you get what you pay for.

Next, a decorative layer is fused on top of the core. Just like a laminate benchtop, the decorative layer is actually a photographic image – usually a woodgrain but sometimes stone or terrazzo – that is printed onto a type of “living paper”.

Finally, a transparent wear layer is applied over the décor layer and this is then given one or more coats of aluminum oxide. The aluminum oxide surface provides incredible wear resistance against scratches, burns, dents, and stains which has made laminate flooring so popular. (OK – for our American members, it’s aluminum oxide!)

Then we get to the locking system. There are various patented systems but they all share a common theme. It’s the system or the way the laminate boards will click and lock together to form your floor in a glue-free method.

The ‘click system’ is what makes installing laminate floors something that any average home-owner can do themselves.

Note that the boards must be laid on a special underlay which acts as a noise suppressor and also ‘softens’ the feel underfoot. I recommend a minimum 3mm (1/8″) underlay with a vapor barrier. The underlay will also help with any minor imperfections in the original floor although major challenges will need to be fixed before laying your floor.

A final suggestion (or two)…

All laminate flooring comes in lengths of about 1,300mm (51″) with each pack covering around 1.4 m2 (14 sq. ft.). This makes the packs and individual boards easy to handle while also minimizing wastage.

Thicknesses range from 6mm (1/4″) to 13mm (1/2″). It is essential that you make sure you can get the correct trims for your chosen floor before buying your laminate. My chosen flooring was 10mm. My retailer (Bunnings) told me after I had paid and taken delivery, that 10mm trims were not available. I had to spend hours modifying 13mm trims to get a satisfactory result. To add insult to injury, I later discovered that 10mm trims do exist but that Bunnings chose not to stock them because, according to the Formica Industries rep I spoke with, the profit margins do not meet Bunning’s requirements!

Note that in regard to thicknesses, my experience has shown me that you need to go to a minimum 8mm board to get a quality ‘underfoot’ feel.

Finally, we get to widths! The width of the ‘planks’ can vary from the ‘narrow’ boards from 115mm – 125mm (4 5/8″ – 5″) to ‘wide’ boards of around 230mm – 250mm (9″ – 10″).

In the job described in this post, I used the narrow boards, which, with their beveled edges look beautiful as a finished job. However, and it’s very big, however, there is insufficient ‘grip’ between the boards and the underlay to prevent movement between adjoining boards. This is not something I have ever experienced with the wider boards. The bottom line is that I would always choose a wide board for any future project I do.

Installing Skirting on Laminate Flooring

Many laminate floors emit a distinct chemical-like odor, often described as a “smoke-like” smell. This scent can be off-putting, especially on newly installed or low-quality laminate flooring. However, skirting, or baseboard, can play a vital role in mitigating this issue.

By providing a protective barrier between the floor and the wall, skirting boards minimize the emission of odors and prevent them from permeating the room.

Additionally, opting for skirting boards made from materials with low VOC (volatile organic compounds) emissions can further improve indoor air quality and create a more pleasant living environment.

While laminate flooring is an economical choice, it may not always provide the most visually pleasing look. The edges where the floor meets the walls can often appear unfinished or uneven. Skirting boards offer a simple, yet effective way to conceal these imperfections.

Available in various styles, colors, and finishes, skirting boards can complement the laminate flooring and enhance the overall aesthetic appeal of the room. They can create a cohesive and polished look, providing a finishing touch that ties the entire space together.

One of the main drawbacks of laminate flooring is the noise it generates when walked upon. The hard surface amplifies sound, resulting in an echoing effect that can be quite frustrating, especially in high-traffic areas.

This noise pollution can disturb household members, pets, and even neighbors. However, this issue can be mitigated by the strategic installation of skirting.

I hope that helps you with your ‘should we or shouldn’t we‘ thoughts. Laminate flooring is a wonderful, robust, easy-to-maintain product. But it is not perfect.