Last Updated on October 30, 2025 by teamobn

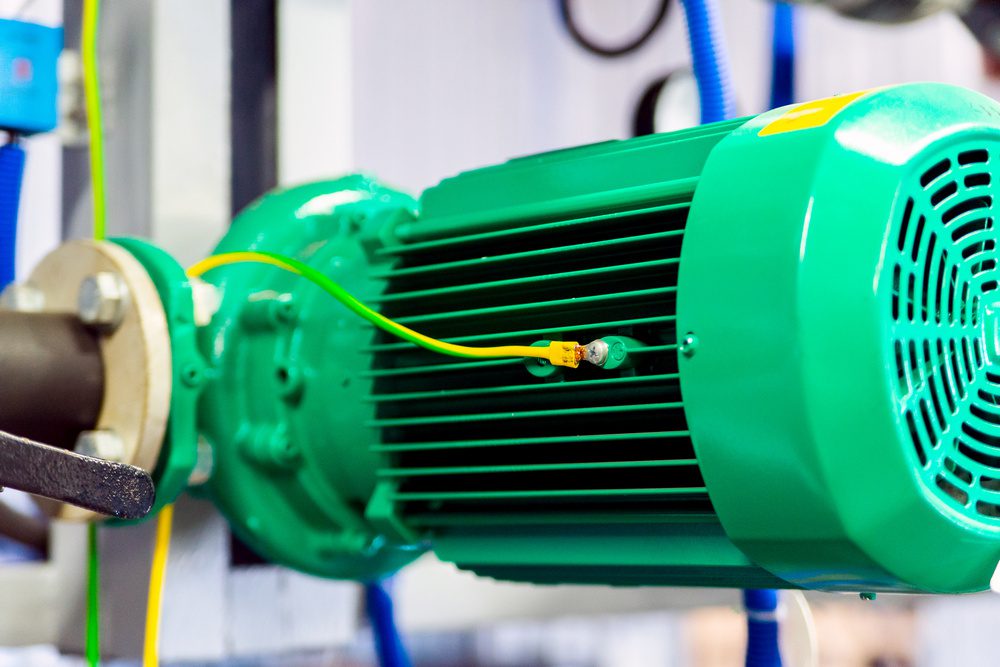

A vacuum pump is commonly used in various industrial manufacturing processes such as packaging, drying, and degassing. It’s a utility that’s used to create and maintain a vacuum in those processes.

It’s utilized in various industries and establishments, including laboratories, the medical field, food packaging, and the chemical industry.

There are many types of vacuum pumps available, but which one is the right fit for your application? This guide features a list of the most popular pump types and their associated components. Understanding the various types of vacuum pumps and how they work will allow you to make an informed choice when selecting the most suitable one for your needs.

What Is A Vacuum Pump?

This is a mechanical device that pulls air or gas from a tank to create a partial or complete vacuum in the system being vacuumed. The air is drawn in as the pressure in the restricted space gradually decreases. The gaseous molecules taken in are then released into the surrounding air or another tank.

It’s critical to consider whether or not the vacuum pump has to be lubricated. The efficiency and resistance of a lubricated vacuum pump are higher. It does, however, necessitate extensive maintenance regularly. A vacuum pump is typically categorized as wet or dry. The former refers to technologies designed to create a vacuum after compression. In contrast, the latter refers to an oil-free or oil less electric vacuum pump for pipelining.

Wet pumps often use oil or water to lubricate and seal themselves. This fluid can contaminate the gas that’s being pumped. On the other hand, dry vacuum pumps have no oil or water in their systems. But even if they’re oil-free, they’re also prone to contamination. Oil or grease can still be used in their gears and bearing connections.

How To Choose The Right Vacuum Pump

There are four factors you need to know before you can pick the right vacuum pump for your pipeline:

- Total head or pressure against which it has to work

- Intended flow rate

- Suction lift

- Fluid’s characteristics

Also, when choosing a vacuum pump, it’s essential to take into account other factors. Some of those include the type of operation you want to perform and the desired flow rate. The ideal vacuum level should be the focus when choosing a pump. There are various vacuums out there such as a low vacuum, a high vacuum, and an ultrahigh vacuum.

Aside from the obvious requirement of having a way to pump water, it’s also required that you understand things like temperature ranges, corrosiveness, and how much and what kind of trash and debris may be present in the water. These are the factors you need to consider in choosing the right pump for your pipelining.

Types Of Vacuum Pump

Horizontal and vertical centrifugal pumps are the two most common configurations. Pumps that employ centrifugal force to transport water from one location to another and overcome flow resistance are called centrifugal pumps. This pump’s most basic design has an impeller mounted on a revolving shaft inside a spiral-shaped casing.

The shape and location of the shaft are the key differences between these two pumps. Centrifugal inline pumps with horizontal shafts go by the moniker ‘horizontal centrifugal inline pumps.’ Either overhangs the bearings or is sandwiched between them. While the horizontal inline pump has a horizontal shaft, the vertical inline pump doesn’t. The shaft has an overhang and is radially split, just like the previous design.

The vertical centrifugal pump is typically used when a horizontal centrifugal pump can’t be used because of the inability to have backward flow, or when there’s no empty site for the horizontal centrifugal pump’s foundation.

Do A Cost Analysis

A cost analysis of water pumping would involve the initial cost of capital investment, operating cost, and annual fixed cost. The factors that affect the cost of water pumping are the size of the pipeline, the type of pump, and the water supply.

A piping system that uses large pipes may cost more than one that uses small diameter pipes. However, it can still provide the same amount of power and require less maintenance. An analysis of all the factors involved in the operation of a pump can help you determine the most efficient option for the specific pipelining projects you’ll be doing.

Takeaway

You must match the pump to the piping system and the needed flow rate to get a pumping system that meets your needs and does so efficiently. There should be pump curves available from the manufacturers that illustrate the pump’s performance and acceptable operating ranges. If you operate the pump outside of this range, it could be damaged.

It’s possible for your dealer to assist you with the design or analysis of your plumbing system. Thus, knowing the factors mentioned here can help you in choosing the most ideal vacuum pump for your pipelining.