Last Updated on January 30, 2018 by teamobn

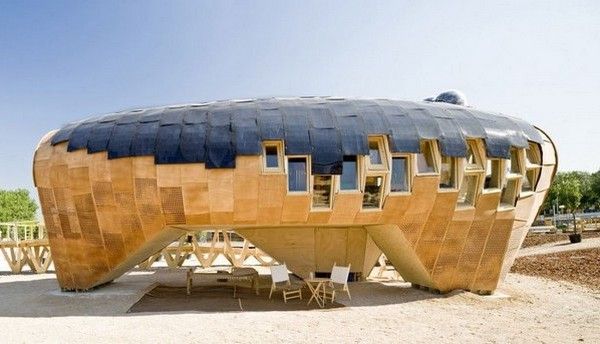

Catalonia, Spain – Institute for Advanced Architecture of Catalonia (IAAC)

Built area: 75 m2 (810 sq. ft.)

Year built: 2010

Photography: Adrià Goula

Designed and built as an entry in the 2010 Solar Decathlon Europe, this home definitely deserves a guernsey in our sustainable homes collection. The objective of the competition is to disseminate the benefits of using renewable energies, especially solar energy, at home.

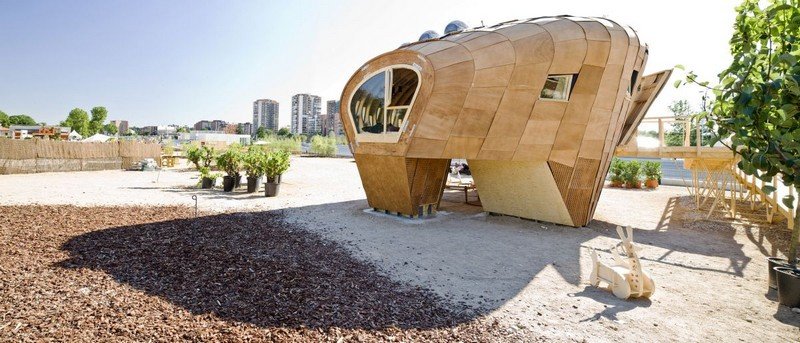

Prefabricated from laser cut materials – predominantly plywood, FabLab house has a photovoltaic skin to harness solar radiation with maximum efficiency. Built on three legs it provides space underneath for natural ventilation and a shaded outdoor living. The home also features smart energy and temperature-monitoring systems and a rainwater collection system.

From the designers and builders:

“The Solar House is a new generation FabLab home whose goal is to not industrialize but allow any person to manufacture anywhere in the world, from the platform of Fab Labs, or fabrication laboratories.The production methodology of the house is founded in a structure fabricated from common materials sourced globally (plywood panels, etc.), and in the use of locally found machinery (laser cutting and/or milling machine). It is definitely a very affordable housing solution, designed with a combination of simple construction, geometric sophistication and technological wealth, both in its creation as an energy system as well as in the active and passive management of the house.

MATERIAL SELECTION

The selection of wood, not steel, as the basic structural material is deduced from two lines of thought, the first being that a solar house must be reduced from a solar material and the second that the choice of wood leads to structural elements and components which are small, light and manageable. Thus material, scale of building elements and level of technology used will be selected not for their excellence and functional optimization, but also by its availability and ease of use and maintenance.

CONSTRUCTION AND ASSEMBLY

We propose a pre-fabricated wooden construction in which all its structural components are laser cut from a 1220x1440mm plywood sheet. These components are then assembled and transported in transversal ring sections to site. Upon arrival to site, each section is then lifted and fixed into place.

TECHNOLOGICAL EFFICIENCY

Through the utilisation of a global network of production laboratories (FabLab’s), we begin to promote the idea of using the Internet to make things. The computer, attached to a laser cutter allows you to print a chair, for example, with a wood-cutting machine and then assemble it. The prototype reduces energy expenditure by 25%, It is through the use of such passive techniques that we aim to use technology, of fabrication and within installed components (i.e. solar panels), efficiently. We propose to measure this efficiency by the relationship between price, availability, complexity / opacity of technology, usability, ease of assembly, maintenance and how malleable it is to the design process.

DISTRIBUTED INTELLIGENCE

Faced with the typical house model of a “box construction” made up of standard industrialized components, we chose to build a clever house with systemic

logic components, rising into what we call a distributed intelligence. This means that each component of the prototype contains the same level of technology, energy, structural, etc… With this we say that the logic of all is found in each of the parts, and not vice versa.

That is, distributed intelligence can be understood as the development in fusion research systems and materials, implying a change of procedures, multi functionality in the construction field. Opening the possibilities of digital parametric design from the traditional assembly of standardized industrial components of the home-computer

Understanding the process from its base, instead of relying on market products, the IAAC is working with MIT to develop devices that allow us to merge building systems, the creation of an intelligent infrastructure, ‘Internet 0’. A single component which can manage complex insulation, ventilation, water collection and yet, through their assembly and structure, enclose a space. This brings us to the concept of skin as a tissue- complex, adaptable and multifunctional. The skin initiates dynamic responses to external variables through simple sensors, mechanisms and programs integrated onto an open hardware platform based on simple inputs and outputs and not have to go through the typical, expensive home automation protocols.

This is the first house to be digitally created that can be manufactured anywhere in the world, through the network of Fab Labs that are in the Americas, South Africa, India, Netherlands, Norway and Spain. Although this prototype has cost more, once the exclusivity is taken away, costs will be lower.

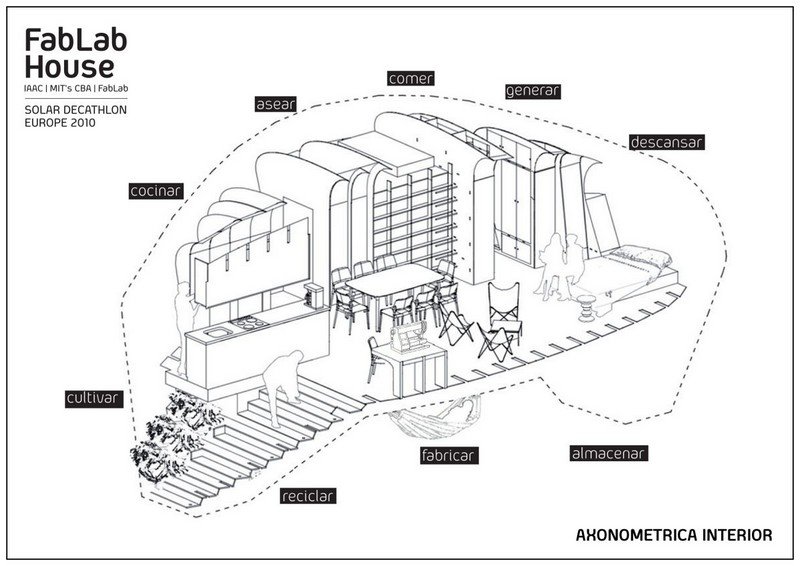

The Solar House can comfortably accommodate a family of 4 within 75 m2 and this makes it possible to fabricate and build the entire dwelling under fifteen days. The Solar House’s aim is to reduce the projected cost ,with further development, to make it more market viable.The IAAC has considered the project from the viewpoint of material efficiency, customization and cost reduction, proposing a customizable home that is very affordable, to the extent it will also reduce overall production costs.

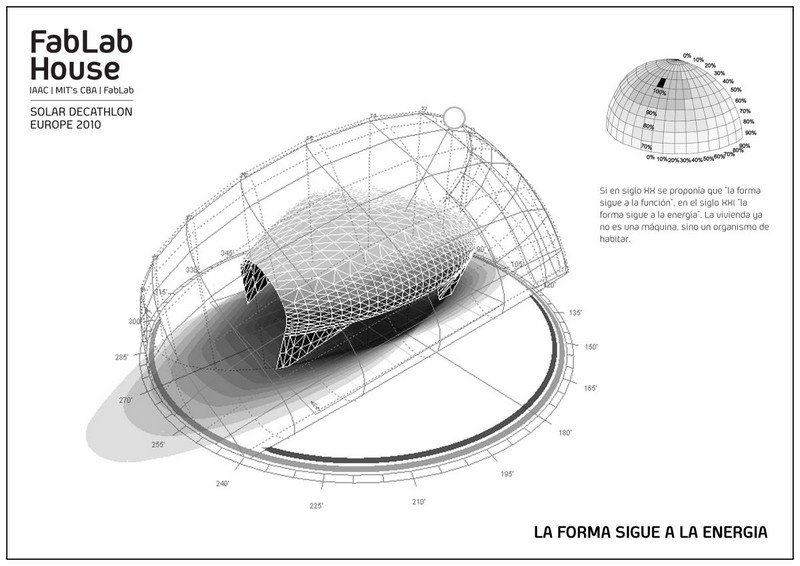

GEOMETRY

A standard paraboloid section is positioned for suitable solar tracking (per year per day), and deformed in appropriate steps aimed towards an optimal orientation for summer (narrowing to the west, eastward widening and flattening toward the zenith of 70 degrees) . The freedom we get from the paraboloid prototype model allows us to swiftly and smoothly adapt the prototype’s envelope to strategic solicitations we want to impose.

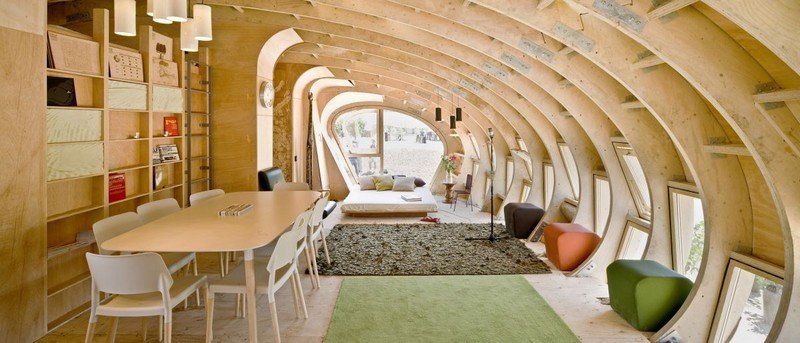

SPATIAL

The Solar Fab Lab house not only has a rounded shape that allows for maximum internal volume with minimal exterior surface but is elevated off the ground upon three ‘legs’, in order to create a space under the house for the development of certain outdoor activities. Using the shade of the house itself to create a space through which cooled air can be introduced into the home when required for natural ventilation. This simultaneously creates a comfortable outdoor space, doubling the living area. These three ‘legs’ are not only structural but are also specialization points for programs and technical equipment for ground level access.”

Click on any image to start lightbox display. Use your Esc key to close the lightbox. You can also view the images as a slideshow if you prefer 😎

You’ll find a link to a video below the image gallery.